Tactile Engine Prototype

NATIONAL AIR AND SPACE MUSEUM

SCOPE OF WORK

The National Air and Space Museum (NASM) was awarded a grant from the Smithsonian

Accessibility Innovations Fund (SAIF) to create an accessible prototype of a hands-on engine

interactive in preparation for NASM’s upcoming Nation of Speed exhibition. The goal of the

interactive is to help visitors understand how engines generate speed and how they can be

modified to go faster. SIE worked with NASM to develop, design, produce, and program the

prototype, which was based on a Ford Flathead V-8 engine. The result was a multi-sensory

experience incorporating tactile components, audio, and lights.

Read more about the project on our blog here:

https://exhibits.si.edu/a-souped-up-prototype/

The fully assembled prototype in “stock mode” (left) and “performance mode” (right)

Short SAIF Engine demonstration video

The prototype interactive was modeled after a Ford Flathead V-8 Engine.

Diagram of Proposed Changeable Components

Molding the Engine Parts: The engine prototype requires both stock and perfomance parts.

SIE used a foam model of the Ford Flathead V-8 Engine to model some of the prototype components. (above)

SIE purchased real performance parts and cast rubber molds to create prototype parts, such as the performance cylinder heads. Molding prep (above), foam molds and resin cast prototype parts (below).

Using the molds we made from the performance parts, SIE cast the parts in urethane foam, added magnets and locating pins, then painted the casts for durability.

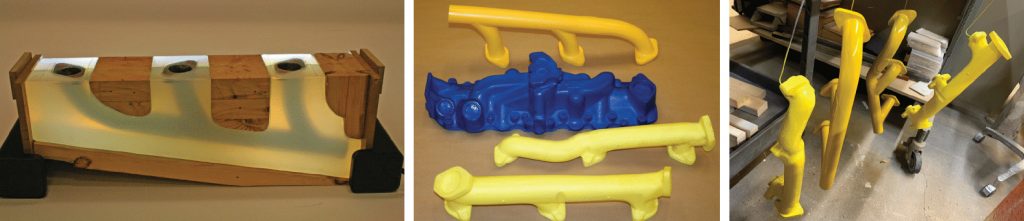

Translucent molds for headers (left)

Foam cast samples (center)

Cast and painted headers (right)

Electronic Interactive Components

The LEDs, speakers, and touch-activated vibrators are all controlled by an Arduino microcontroller. (left)

SIE prototyped the electrical light, sound, and vibration components with an evolving circuit layout. SIE made clear casts of spark plugs and incorporated red and white LEDS. (center and right)